Xilliga xagaaga kulul ama jiilaalka qabow, qaboojiyaha baabuurtu waa lama huraan annaga oo jecel baabuurta, gaar ahaan marka daaqadaha ay ceeryaamo noqdaan ama ay barafoobaan. Awoodda nidaamka qaboojiyaha si dhakhso ah u dhalaaliyo oo u dhalaalaan waxay door muhiim ah ka ciyaartaa badbaadada wadista. Gawaarida korontada ku shaqeeya, oo aan lahayn matoor shidaal, ma haystaan il kuleyl ah oo ay ku kululeeyaan, kombaresaradana ma laha awoodda wadista matoorka si ay u bixiyaan qaboojinta. Haddaba sidee bay baabuurta korontada ku shaqeeya ee saafiga ah u bixiyaan hawlaha qaboojinta iyo kululaynta qaboojiyaha? Aan ogaano.

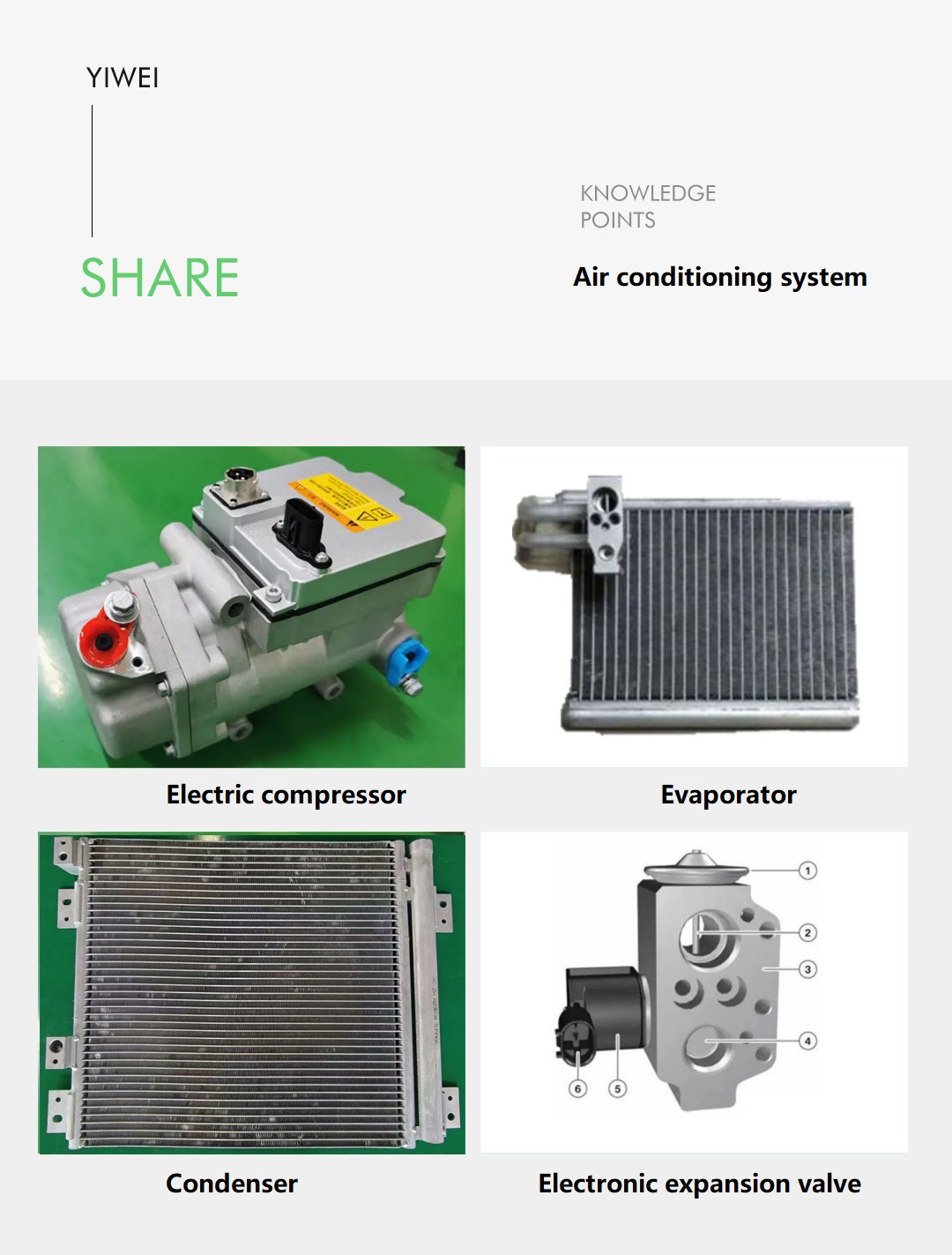

01 Qaybaha Nidaamka Qaboojinta Hawada

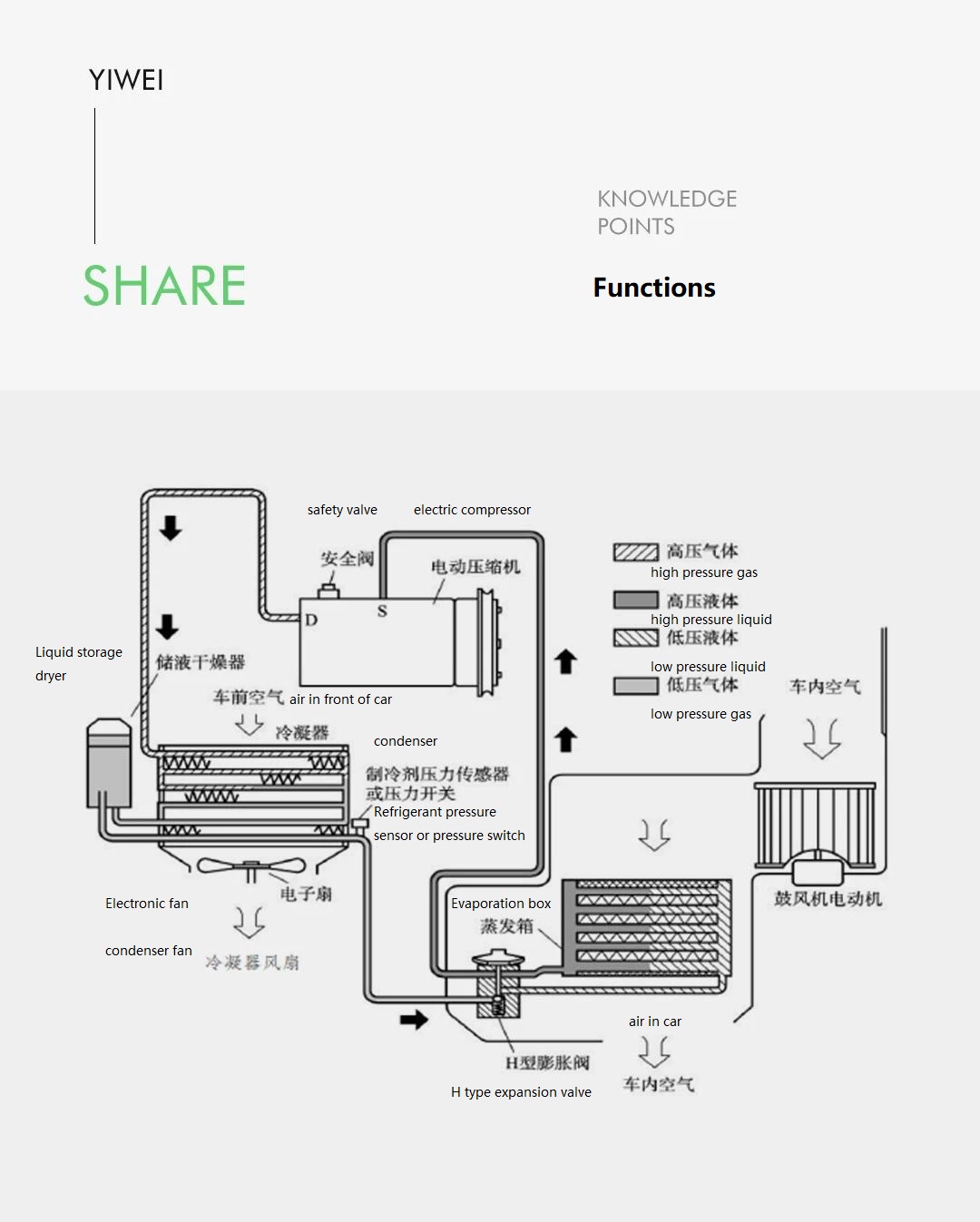

Qaybaha nidaamka qaboojinta qaboojiyaha waxaa ka mid ah: kombaresarada korontada, kondenserka, dareemaha cadaadiska, waalka ballaarinta elektaroonigga ah, uumi-bixiyaha, tuubooyinka adag ee qaboojiyaha, tuubooyinka, iyo wareegga xakamaynta.

Kombaresarada:

Waxay qaadataa qaboojiyaha gaaska ee heerkulka hooseeya iyo kan cadaadiska hooseeya waxayna ku cadaadisaa gaaska qaboojiyaha dareeraha ah ee heerkulka sare iyo kan cadaadiska sare leh. Inta lagu jiro cadaadiska, xaaladda qaboojiyaha isma beddelin, laakiin heerkulka iyo cadaadiska ayaa si joogto ah u kordha, iyagoo sameeya gaas aad u kulul.

Kondenserka:

Kondenserku wuxuu adeegsadaa marawaxad qaboojin oo u gaar ah si uu kulaylka qaboojiyaha heerkulka sare iyo cadaadiska sare ugu daadiyo hawada ku xeeran, isagoo qaboojinaya qaboojiyaha. Habkan, qaboojiyaha wuxuu ka beddelaa xaalad gaas ah una beddelaa xaalad dareere ah, wuxuuna ku jiraa xaalad heerkul sare iyo cadaadis sare leh.

Waalka Ballaarinta:

Qaboojiyaha dareeraha ah ee heerkulka sare iyo cadaadiska sare leh ayaa dhex mara waalka ballaarinta si uu u joojiyo cadaadiska oo uu u yareeyo cadaadiska ka hor inta uusan gelin uumi-bixiyaha. Ujeeddada habkan ayaa ah in la qaboojiyo oo la yareeyo cadaadiska qaboojiyaha iyo in la habeeyo socodka si loo xakameeyo awoodda qaboojinta. Marka qaboojiyaha uu dhex maro waalka ballaarinta, wuxuu ka beddelaa dareere heerkul sare, cadaadis sare leh una beddelaa dareere heerkul hoose, cadaadis hoose leh.

Uumi-bixiyaha:

Qaboojiyaha dareeraha ah ee heerkulka hooseeya, cadaadiska hooseeya ee ka yimaada waalka ballaarinta ayaa nuugaya kulayl badan oo ka imanaya hawada ku hareeraysan ee uumi-bixiyaha. Inta lagu jiro hawshan, qaboojiyaha ayaa isu beddelaya dareere una beddelaya gaas heerkul hooseeya, cadaadis hooseeya. Gaaskan waxaa markaa nuugaya kombaresarada si uu mar kale u cadaadiyo.

Marka laga eego mabda'a qaboojinta, nidaamka qaboojiyaha ee baabuurta korontada ku shaqeeya asal ahaan waa la mid ah kan baabuurta caadiga ah ee shidaalka ku shaqeeya. Farqiga ugu weyn wuxuu ku jiraa habka wadista ee kombaresarada qaboojiyaha. Gawaarida caadiga ah ee shidaalka ku shaqeeya, kombaresarada waxaa ku shaqeeya suunka matoorka, halka baabuurta korontada ku shaqeeya, kombaresarada waxaa lagu maamulaa kontoroolka elektarooniga ah si loogu wado matoorka, kaas oo isna ku shaqeeya kombaresarada iyada oo loo marayo shaftka crankshaft.

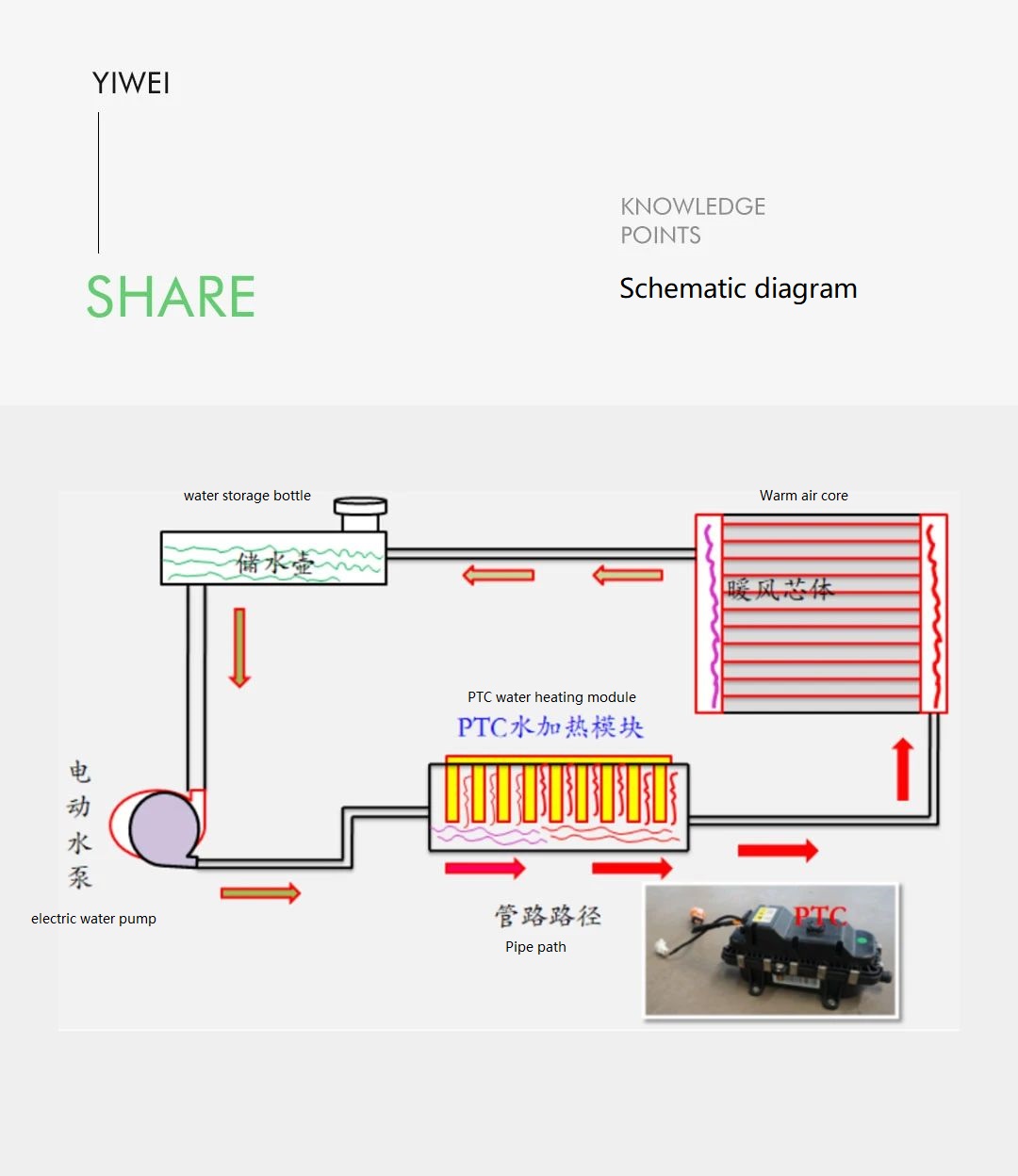

02 Nidaamka Kuleylka Qaboojiyaha Hawada

Isha kuleylinta waxaa inta badan laga helaa kuleylinta PTC (Positive Temperature Coefficient). Gawaarida korontada ee saafiga ah guud ahaan waxay leeyihiin laba qaab: moduleka PTC ee kuleylinta hawada iyo moduleka PTC ee kuleylinta biyaha. PTC waa nooc ka mid ah kuleyliyaha semiconductor-ka, astaamaheedana waa in iska caabbinta walxaha PTC ay korodho marka heerkulku kor u kaco. Marka uu jiro danab joogto ah, kuleyliyaha PTC si dhakhso ah ayuu u kululaadaa heerkul hooseeya, marka heerkulku kor u kaco, iska caabbintu way korodhaa, hadda way yaraataa, tamarta ay isticmaasho PTC-na way yaraataa, sidaas darteedna waxay ilaalinaysaa heerkul joogto ah.

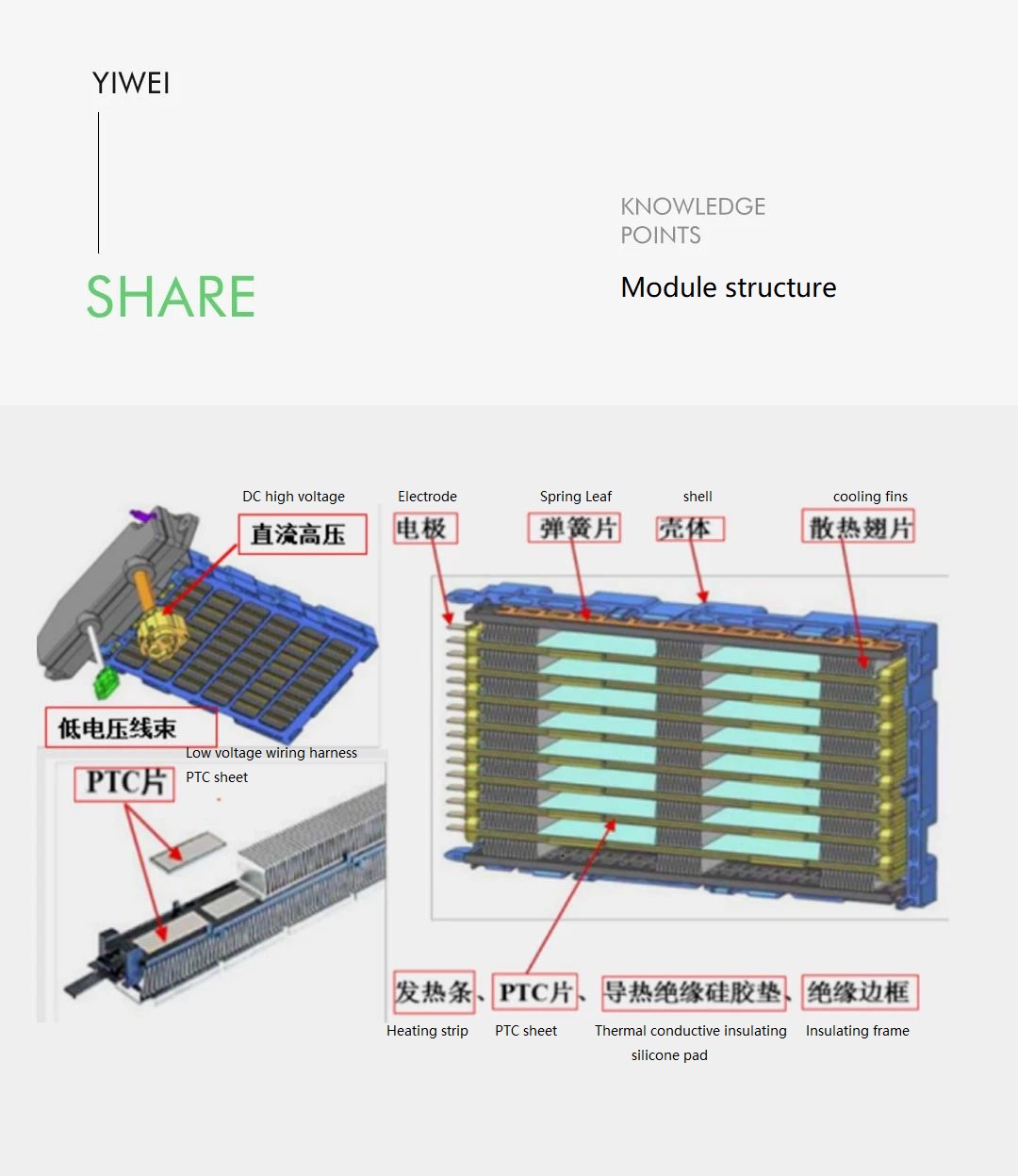

Qaab-dhismeedka Gudaha ee Module-ka Kululaynta Hawada ee PTC:

Waxay ka kooban tahay kontaroole (oo ay ku jiraan module wadista danab yar/danab sare), isku xirayaasha xarigga siligga cadaadiska sare/hoose, filimka iska caabbinta kululaynta PTC, suufka silikoon ee dahaarka leh ee kulaylka gudbiya, iyo qolofka dibadda, sida ku cad sawirka.

Module-ka PTC ee kulaylinta hawada waxaa loola jeedaa in si toos ah loogu rakibo PTC xudunta nidaamka hawada diiran ee qolka. Hawada qolka waxaa ku wareegaya afuufayaha waxaana si toos ah u kululeeya kuleyliyaha PTC. Filimka iska caabbinta kululaynta ee ku jira module-ka PTC ee kulaylinta hawada waxaa ku shaqeeya danab sare waxaana maamula VCU (Cutubka Xakamaynta Gawaarida).

03 Xakamaynta Nidaamka Qaboojinta Hawada ee Gawaarida Korontada

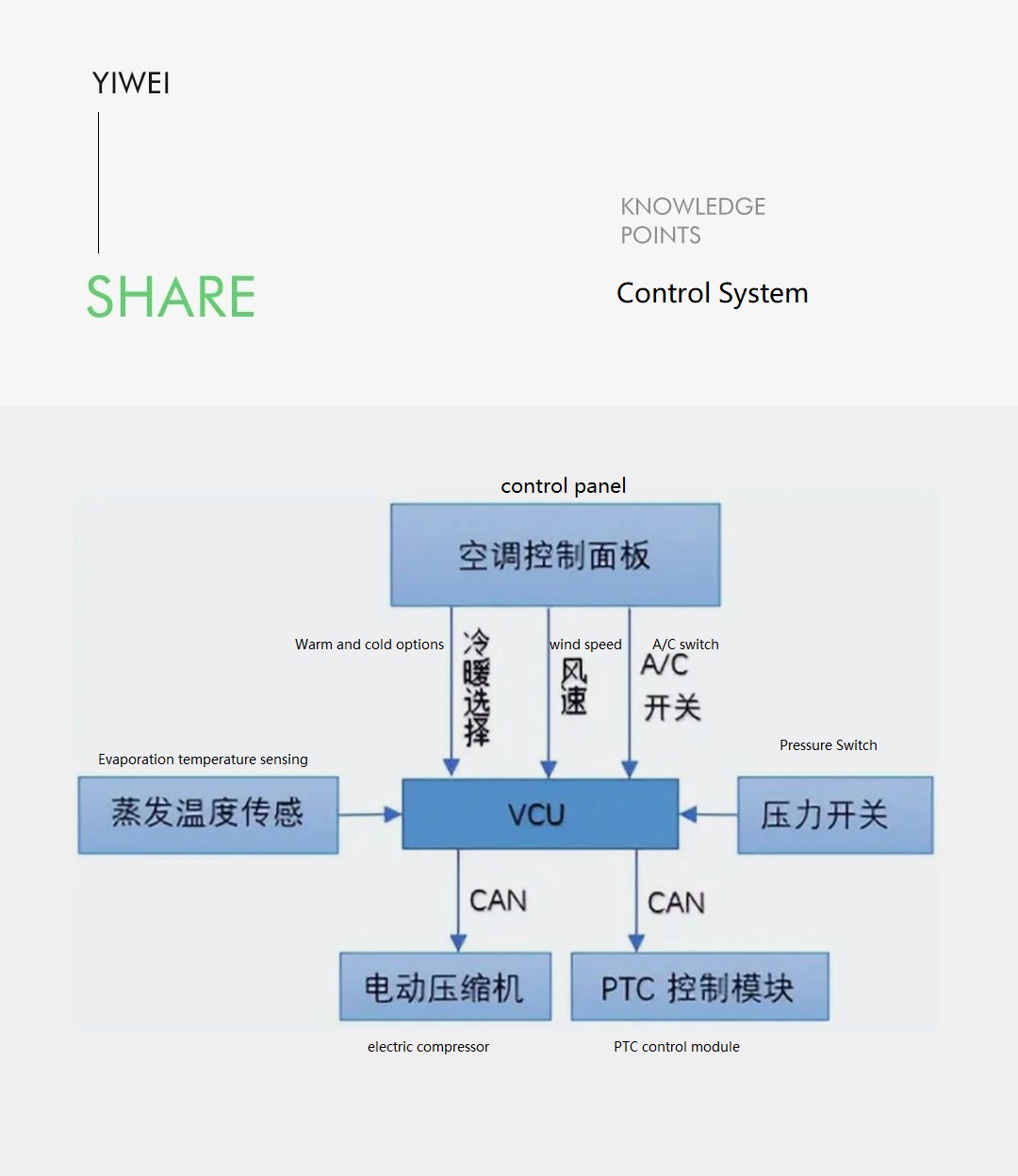

VCU-ga gaariga korontada ku shaqeeya wuxuu ka soo ururiyaa calaamadaha badhanka A/C, badhanka cadaadiska A/C, heerkulka uumiga, xawaaraha taageeraha, iyo heerkulka deegaanka. Ka dib marka la farsameeyo oo la xisaabiyo, wuxuu soo saaraa calaamadaha xakamaynta, kuwaas oo loo gudbiyo koontaroolaha qaboojiyaha iyada oo loo marayo baska CAN. Koontaroolaha qaboojiyaha wuxuu xakameeyaa shidista/daminta wareegga danab-sare ee kontaroolaha qaboojiyaha, sida ka muuqata sawirka.

Taasi waxay soo gabagabaynaysaa hordhaca guud ee nidaamka qaboojiyaha hawada ee baabuurta korontada ku shaqeeya. Ma u aragtay mid waxtar leh? La soco Yiyi New Energy Vehicles si aad u hesho aqoon xirfadeed oo dheeraad ah oo la wadaago toddobaad kasta.

Nala soo xiriir:

yanjing@1vtruck.com +(86)13921093681

duanqianyun@1vtruck.com +(86)13060058315

liyan@1vtruck.com +(86)18200390258

Waqtiga boostada: Sebtembar-13-2023